2025-11-19 06:08:39

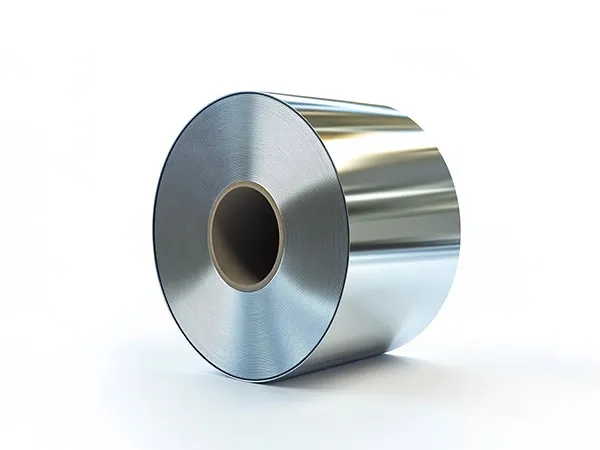

Aluminum coils are essential in modern industrial, construction, and architectural projects, offering lightweight, durable, and corrosion-resistant solutions. Choosing the right aluminum coil finish—pre-painted aluminum coils or anodized aluminum coils—can significantly influence both performance and appearance. Understanding their benefits, applications, and differences helps manufacturers, designers, and engineers make informed material decisions.

Pre-painted aluminum coils, also known as PVDF or coil-coated aluminum, are coated with a protective paint layer during production. This coating enhances aesthetics with vivid colors, textures, and finishes, while also improving corrosion resistance and weather durability.

Key Benefits:

Customizable Appearance: Wide range of colors, textures, and finishes for architectural panels and industrial applications

Long-Lasting Protection: Resistant to UV, moisture, and environmental pollutants

Low Maintenance: Smooth surfaces are easy to clean and maintain

Typical Applications:

Building facades, roofing panels, and cladding

Signage, advertising boards, and decorative elements

Interior and exterior architectural designs

Anodized aluminum coils undergo an electrochemical process that thickens the natural oxide layer, producing a hard, corrosion-resistant surface. Unlike paint, anodizing penetrates the aluminum itself, offering durability and longevity without added bulk.

Key Benefits:

Enhanced Corrosion Resistance: Ideal for coastal, industrial, and outdoor environments

Scratch and Wear Resistance: Suitable for high-traffic or heavy-duty applications

Sustainable and Recyclable: Fully metal-based and environmentally friendly

Typical Applications:

Window frames, curtain walls, and architectural panels

Automotive components and machinery parts

Electrical and electronic housings

Selection depends on project requirements, environmental exposure, and aesthetic needs:

Pre-painted aluminum coils are perfect for projects requiring design flexibility, vibrant colors, and decorative finishes

Anodized aluminum coils are ideal for durable, corrosion-resistant, and long-lasting applications

Both pre-painted and anodized aluminum coils offer distinct advantages in modern construction, manufacturing, and industrial projects. By understanding their properties, benefits, and applications, businesses can optimize material selection, enhance product performance, and ensure long-term value. Choosing the right aluminum coil finish guarantees that your projects look great, perform reliably, and withstand the test of time.