2025-06-12 06:57:56

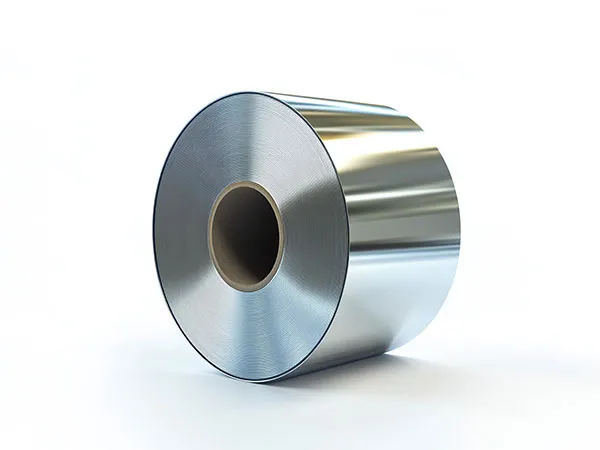

Aluminum coil is an incredibly versatile material used across a vast range of industries due to its unique combination of properties. Essentially, an aluminum coil is a flat sheet of aluminum that has been rolled up, making it easier to transport, store, and process into various products.

Here are the main reasons why aluminum coil is so widely used, and some of its common applications:

Lightweight: Aluminum is significantly lighter than many other metals, like steel, making it ideal for applications where weight reduction is crucial (e.g., transportation).

Corrosion Resistance: It naturally forms a protective oxide layer that resists rust and corrosion, even in harsh environments. This makes it excellent for outdoor and marine applications.

High Strength-to-Weight Ratio: Despite being lightweight, certain aluminum alloys can be very strong, offering excellent structural integrity.

Malleability and Formability: Aluminum is highly ductile and malleable, meaning it can be easily formed, stamped, bent, drawn, and shaped into complex parts without breaking.

Thermal and Electrical Conductivity: It's an excellent conductor of heat and electricity, making it suitable for electrical components and heat transfer applications.

Reflectivity: Aluminum has high reflectivity, which is useful in lighting and insulation.

Building and Construction:

Roofing and Siding: Lightweight, corrosion-resistant, and can be pre-painted for aesthetic appeal.

Facade Panels and Cladding: Used for exterior building envelopes.

Window and Door Frames: Durable and weather-resistant.

Ceilings: Aluminum ceilings are popular in commercial and public spaces.

Insulation: Due to its reflective properties, it's used in insulation materials.

Gutters and Downspouts: Corrosion resistance is key here.

Transportation:

Automotive Industry: Used for vehicle bodies, engine components (e.g., radiators), wheel hubs, and interior parts, contributing to "lightweighting" for fuel efficiency.

Aerospace Industry: Aircraft fuselages, wings, and other structural components due to its strength-to-weight ratio.

Marine Applications: Ship hulls and other marine equipment due to corrosion resistance in saltwater.

Trailer Body Liners: Durable and flexible.

Packaging:

Beverage Cans: The most common application for aluminum coil in packaging.

Food Containers: For various canned and packaged food products.

Foil Packaging: Aluminum foil for food wraps, pharmaceutical packaging (blister packs), etc.

Lids and Bottles: For various consumer goods.

Electrical and Electronics:

Heat Exchangers and Heat Sinks: Excellent thermal conductivity for dissipating heat in electronics and HVAC systems (e.g., air conditioners, refrigerators).

Electrical Components: Used in various household appliances, electronic devices, switchgear housing, and transformers.

Wiring: While copper is superior for conductivity, aluminum is used for power transmission lines due to its lighter weight and cost-effectiveness.

Shielding: Can reduce electromagnetic interference.

Consumer Goods:

Kitchen Utensils and Cookware: Due to its heat conductivity and non-toxic nature.

Household Appliances: Used for interior and exterior components.

Sporting Equipment: Bicycles, skis, and other gear benefiting from lightweight and strength.

Decorative Items and Jewelry: Can be easily shaped and finished.

Industrial Applications:

HVAC/R Systems: Coils, ducts, and other components in heating, ventilation, air conditioning, and refrigeration.

Machinery Parts: Various components that require a balance of strength, weight, and corrosion resistance.

Storage Tanks and Containers: For various industrial fluids.

Signage and Advertising Boards: Can be pre-painted and easily fabricated.

Aluminum coil is available in various alloys (e.g., 1100, 3003, 5052, 6061, 8011) and tempers, which are chosen based on the specific mechanical properties, formability, and corrosion resistance required for the intended application.