2025-11-09 02:39:08

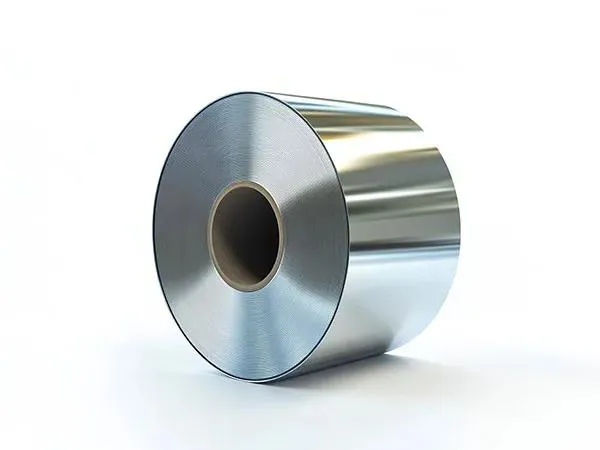

Choosing the right aluminum coil thickness is a critical step that can make or break your project’s success. From construction and automotive manufacturing to aerospace and packaging, selecting the optimal coil ensures durability, flexibility, and cost-efficiency. In this comprehensive Aluminum coil thickness guide, we’ll walk you through the key factors to consider, common thickness ranges, and expert tips to help you make informed decisions and maximize performance for your specific application.

Selecting the right aluminum coil thickness is a crucial step that directly affects both project performance and material cost-efficiency. Whether your project involves construction, automotive manufacturing, aerospace components, or packaging solutions, understanding how to match coil thickness to your requirements ensures optimal results and long-lasting performance.

Aluminum coils come in a variety of thicknesses, typically measured in millimeters or gauge. The thickness you choose impacts several critical factors:

Structural Strength: Thicker coils provide greater durability and load-bearing capacity, ideal for roofing, siding, and industrial structures.

Flexibility and Forming: Thinner coils are easier to bend, cut, or roll, making them perfect for automotive panels, decorative designs, and lightweight components.

Weight Considerations: Lighter coils reduce overall project weight, crucial in aerospace, transportation, and energy-efficient applications.

Cost Efficiency: Choosing a coil thicker than necessary increases material costs, while too thin may compromise performance.

Application Requirements

Identify the primary function of your aluminum coil. Structural projects require thicker coils, while decorative or lightweight applications can perform well with thinner materials.

Environmental Conditions

Consider the operating environment: exposure to moisture, extreme temperatures, or corrosive elements may necessitate thicker or specially coated coils.

Processing and Fabrication Needs

Coil thickness affects manufacturability. Ensure the material is compatible with stamping, bending, rolling, or cutting equipment to avoid production issues.

Standards and Regulations

Certain industries, such as aerospace or food packaging, mandate minimum thickness levels. Always verify compliance with relevant industry standards.

|

Gauge / Thickness |

Typical Applications |

|

Light Gauge (0.2–0.5 mm) |

Decorative panels, signage, light-duty applications |

|

Medium Gauge (0.5–1.5 mm) |

Automotive parts, roofing sheets, medium-strength applications |

|

Heavy Gauge (1.5–6 mm) |

Construction, industrial machinery, heavy-duty structural components |

Consult Experienced Suppliers: Industry professionals can advise on the best thickness for your application and budget.

Test Samples: Evaluate sample coils under real-world conditions to ensure performance.

Consider Coatings and Treatments: Pre-painted or anodized aluminum may allow thinner material use without sacrificing durability.

Balance Strength and Cost: Always weigh structural requirements against project budget to avoid over-spending.

Choosing the right aluminum coil thickness goes beyond numbers—it’s about aligning material properties with project requirements, environmental conditions, and fabrication methods. Investing time in proper selection enhances durability, reduces costs, and ensures smooth manufacturing processes.

By understanding thickness ranges, applications, and expert tips, you can confidently select an aluminum coil that delivers long-term performance and maximizes project efficiency.